TGH Aviation Celebrates 60 Year Anniversary

Auburn, CA, March 30th, 2017

TGH Aviation, one of the most trusted and respected Part 145 Repair Stations in the industry, this year celebrates its 60th anniversary. TGH Aviation takes pride in its humble beginnings and appreciates the loyalty and dedication of both customers and employees throughout the past six decades. The company will commemorate the occasion with a number of customer appreciation specials and anniversary promotions throughout the year.

In 1957 founder Emery “Claude” Oxley Senior set out with a vision to specialize in the repair of gyroscopes for General Aviation aircraft. Claude originally began working out of his home in Riverside, California before his son Emery moved the business to a small wooden building in Auburn, California and joined forces with Chief Engineer, Rich Anderson. The early years were critical to the long term success of The Gyro House, now known as TGH Aviation. The founders built a strong infrastructure for the future by developing the TGH Aviation reputation as a top quality aircraft instrument repair facility with superior customer service.

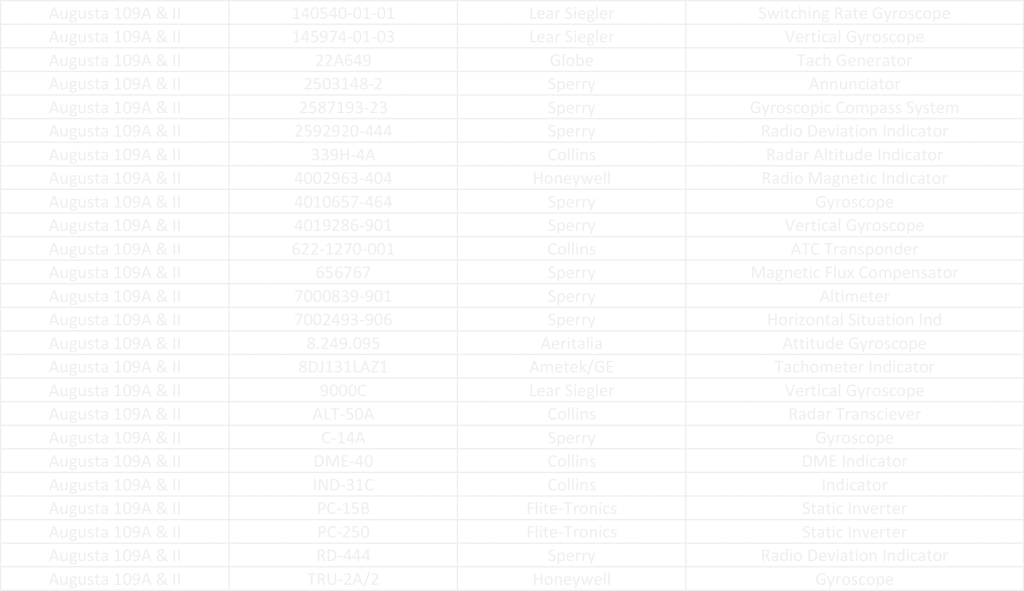

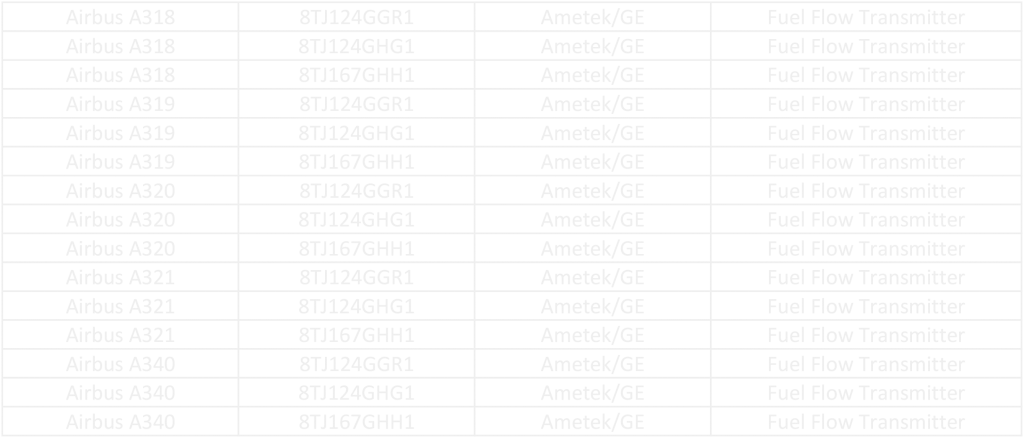

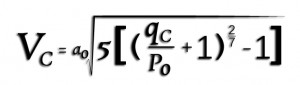

Over the course of the last 60 years, TGH Aviation has vastly expanded its capabilities beyond gyroscopes, evolving into a diverse aircraft instrument repair facility that has become known world-wide. TGH Aviation now offers over 20,000 service capabilities, including the repair of primary flight instruments, avionics, aural warning systems, fuel flow transmitters, and their related indicators and refueling sensors. Today TGH Aviation is a valued supplier to the United States Department of Defense, NATO and a world-wide network of aviation maintenance facilities and parts brokers while still maintaining its legacy customer base of General Aviation pilots.

TGH Aviation provides outright sales, exchange sales, avionic installations and upgrades, repair services, and holds distributorships for most of the major manufacturers of the aforementioned product lines. The company’s repair shop customer base spans all areas of the industry from general aviation, corporate aviation and commercial aviation. The customer base includes airlines, parts brokers and maintenance facilities on five continents.

The past 60 years have been a hugely successful time for TGH Aviation, which now consists of a fully operational repair station, fuel lab, online pilot supply store and an avionics hangar. A veteran-owned company, TGH Aviation employs forward-thinking, growth-oriented management and all employees work to build the company reputation while improving industry presence and stature. The company is delighted to have become a part of the local community and to have had the pleasure of working with and meeting many people over the years and look forward to continuing to build on these strong relationships in the future.

As TGH Aviation looks to the next 60 years the mission continues to be to provide customers with high quality products, overhauls and repairs, all delivered with premiere customer service. As one of the most trusted and respected Part 145 Repair Stations in the industry today, TGH Aviation strives to create a great customer experience each and every time.

For a complete list of capabilities, go to www.tghaviation.com for more information.